Energy Technologies Inc. | Model 510 BTU Meter

Model 510 BTU Meter

The Model 510 BTU Meter is designed to measure as-received ash, moisture, heating value, and weight of bulk materials.

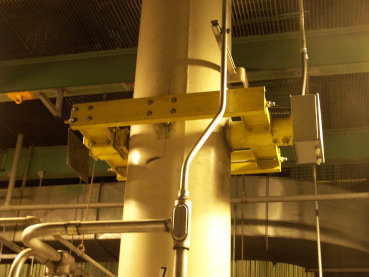

The measuring portion of this device, consisting of a source and detector assembly, is typically mounted on a feeder pipe. The detector is connected to an electronics enclosure which houses an industrial computer. This computer processes the signals received from the detector and displays the measured results to the operator.

The BTU Meter generates measurements every three seconds. These frequent readings are then averaged to produce ash, moisture, heating value, and weight/density values every minute. This consistent and accurate data is made available to plant control systems through direct access to the system's database or via analog and digital outputs provided with the system. This integration ensures that the data is seamlessly incorporated into the plant's overall control processes, facilitating efficient and effective material handling and processing.

BTU Meter on Feeder Pipe

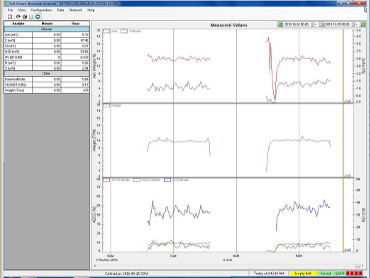

ETI DataView

Return to Products

Return to Products Datasheet

Datasheet