Energy Technologies Inc. | Model 730 Full Stream Elemental Analyzer

Full Stream Elemental Analyzer – Model 730

The ETI Model 730 Full Stream Elemental Analyzer (FSEA) is a cutting-edge online cross-belt analyzer that uses Prompt Gamma Neutron Activation Analysis (PGNAA) and a Dual-Gamma or Single-Gamma instrument to measure the elemental composition, ash, moisture, heating value, and weight of the full material stream in real time as it moves on a conveyor belt.

The analyzer consists of:

- Model 800 Neutron Activation Analyzer – for continuous elemental analysis. Choice of:

- DGA-410(M) Dual-Gamma Ash Analyzer – measures ash, moisture, heating value, and weight.

- Model 500 Nuclear Belt Scale – measures weight.

- • Online, full-stream analysis – no manual sampling needed

- • High-speed PGNAA technology – accurate, non-destructive elemental detection

- • Real-time feedback – adjust material quality while it moves

- • Integration-ready – connect via SQL, analog, or digital output

- • Batch and stockpile reporting – track material quality over time

- • No external mechanical belt scale required – built-in Nuclear Belt Scale function provides material weight required for accurate analysis

- • Variable belt loading allowed – internal scale eliminates need for uniform material depth on conveyor

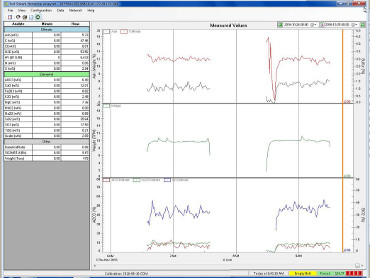

- Direct access to the analyzer's internal SQL database

- Analog and digital output modules in the Data Acquisition Unit (DAU)

- Use of the ETI Dataview Client application on user workstations

True Real-Time, Full-Stream Analysis

Unlike offline sampling systems or XRF, the FSEA provides real-time, full-stream elemental analysis of 100% of the material — no interruptions or sampling required. As material passes through the analyzer, PGNAA sensors deliver precise elemental readings with minute-by-minute updates.

Key Benefits

Easy Integration with Plant Systems

Analytical data from the FSEA is available to your plant systems through:

This connectivity allows your team to automate process adjustments, build consistent stockpiles, and generate detailed reports on material quality by batch or time range.

Dual Analyzer Configuration

ETI DataView

ETI PGNAA Instrument

Applications:

Cement

Typically installed after the quarry crusher and before the Raw Mill, the FSEA allows operators to maintain tight control over cement chemistry before the raw material reaches the kiln. Analyzer data is used by automated plant systems to control additive feeders, thereby maintaining proper chemistry. The analyzer is critical in controlling the quality and consistency of the clinker product.

The FSEA calculates the phase composition proportions of Alite (C3S), Belite (C2S), Tricalcium Aluminate (C3A), and Tetracalcium Aluminoferrite (C4AF). It provides CaCO3, Loss On Ignition (LOI), Lime Saturation Factor (LSF), Silica Ratio (SR), and Alumina Ratio (AR) values, and it directly measures and reports these standard analytes

Coal

FSEAs are utilized in coal mines and coal-fired power plants to provide invaluable data to operators. In both mines and power plants, the FSEA is used to monitor customer-specific coal qualities such as ash, BTU, sulfur, Na2O, and Base-to-Acid ratio in addition to the remainder of the standard analytes.

Other applications include barn, silo, and stockpile management, train and barge loading, sorting, blending, and slagging and fouling mitigation.

Biomass, municipal waste, & wood products

The use of the FSEA in these applications is similar to its use in coal, as they are all used as fuels. The analyzer reports can be supplied with the batches of material run to document its quality.

As in coal applications, the FSEA reports heating value, and ash content. Chlorine, sulfur, and nitrogen are elements of particular concern, and all are reported as standard analytes.

Cement & Minerals Datasheet

Cement & Minerals Datasheet Return to Products

Return to Products